IoT in Manufacturing: Applications and Benefits Explained

IoT In Manufacturing: Applications And Benefits Explained

The Internet of Things is a topic that has been discussed by many people, but what it means and how it can be applied to other industries is unclear. It could be your home, your car, or any other device. Here in this blog we will dive into the aspect of IoT in-depth and understand the benefits and its applications in the manufacturing industry and how IoT development services can help your industrial firm in the best way possible.

What Is the IoT in Manufacturing?

Many manufacturers have realized the benefits of using IoT in their production process. It can help you create an intelligent production line that will respond to environmental changes and enables one-to-one customized manufacturing; which takes away the need for producing custom batches when demand increases or decreases. With the help of an internet-connected device, data can flow seamlessly between a company’s manufactured goods, its customers, and suppliers around the world in real time. Today, IoT is a reality in many companies and is expected to become the standard for most industries shortly, and IoT development companies will benefit the most from it.

What Is an IoT System?

In short, an IoT system refers to any of the various connected devices that send and receive data over a network. Each device has a specific role in the overall system. For example, an office can have an IoT system that will automatically send out alerts when a door or window is open or broken. On another level, it can be used for remote maintenance so that you can replace light bulbs or filters without having to come in person to do it yourself. Devices in an IoT system can also be used to track information on the movement of objects from one place to another. Tools such as 3D printing and other manufacturing processes have advanced so much that they can be controlled directly by an intelligent system in real-time. In addition, if you are looking for an IoT system for your manufacturing industry, then, IoT development solutions from authentic sources like HashStudioz can help you in the best possible ways.

What Are the Main Benefits of an IoT System?

The primary benefit of an IoT system is that it takes physical products offline and makes them digital, which significantly reduces costs and increases time-to-market for your products. By reducing manual labor at a manufacturing facility, you improve efficiency and productivity. If you are intrigued by how IoT works then IoT development solutions are your one-stop solutions.

Customers will find this convenient because they won’t have to stand outside waiting for product delivery or even go through tedious shipping procedures. This will also save your company valuable resources. Consider this; if a customer needs an item that you are unable to fulfil, they can contact you when they have the time and let you know. With an IoT system, customers will see that your product is being produced in real-time as well as stay informed about the status of their product.

The benefits of IoT in the manufacturing industry are huge but that’s not all. As consumers, we know about them and have already seen a lot of positive effects. What’s more, all millennials (those born between 1980 and 1995) will be comfortable with this concept. If we take a look at all the hype that’s surrounding this topic, it’s not surprising how popular it has become. It’s also not surprising that manufacturers and Internet of Things (IoT) startups are working hard to develop IoT products and services and to turn the vision into reality.

The Main Benefits of IoT in the Manufacturing Industry Are:

- Enhancing quality control with remote monitoring systems can help detect problems before they become serious.

- Improving performance and service levels with predictive maintenance applications that pre-empt equipment problems and fix them before they occur.

- Eliminating the need for expensive safety guards with wearable devices that alert staff to potential dangers, or shut down machinery if the risk is too great.

- Reducing carbon emissions, energy usage, and waste with smart grid applications that draw energy from green sources.

- Making factories “greener” by monitoring weather and air quality and controlling indoor conditions, to minimize the use of heating, cooling, ventilation, and lighting systems.

- Boosting efficiency with apps that monitor production lines and parts handling systems in real time.

- Reducing absenteeism and improving staff morale through “intelligent” facilities management apps that save time spent on paperwork and allow employees to work remotely.

- Fueling the growth of machine-to-machine (M2M) and Internet of Services (IoT) applications that enable manufacturers to integrate their machines and processes with outside systems.

- Accomplishing more with fewer people by introducing robots that can do repetitive tasks more efficiently, reduce errors and increase operational efficiency.

- Improving efficiency by providing hospitals with real-time data on patients’ conditions for improved care and reduced costs.

- Encouraging consumers to buy a “smart” car or smartphone at a much lower price, because it is running out of juice because it’s not connected to the Internet.

- Making cities cleaner by helping city planners develop initiatives that can help curb pollution.

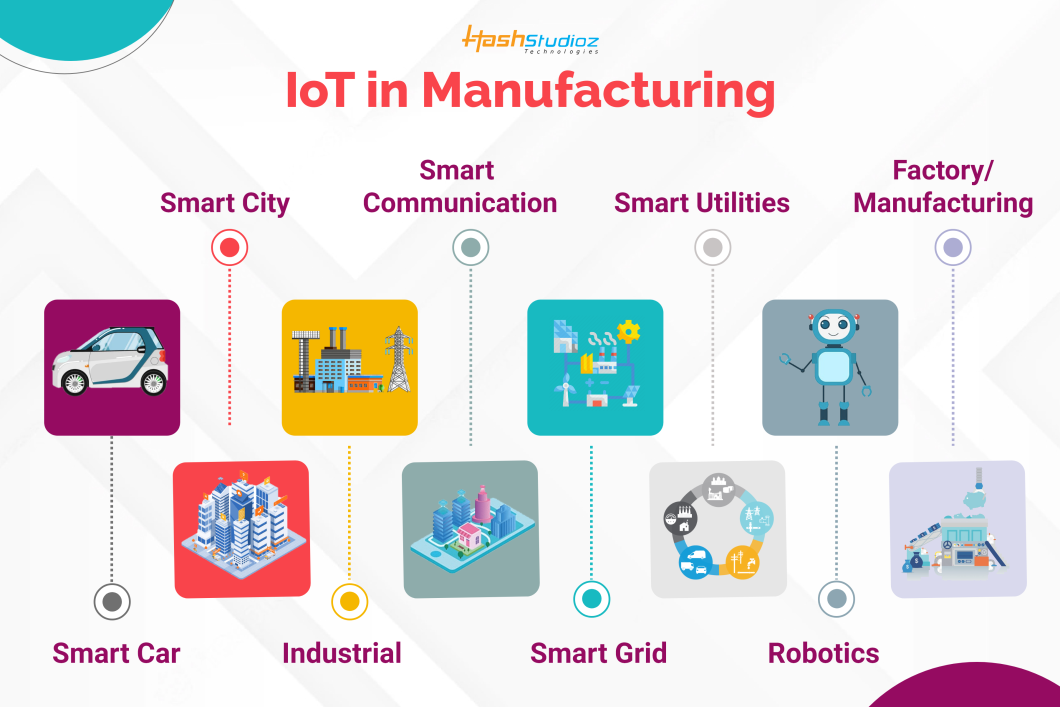

Applications of IoT in the Manufacturing Industry

The Internet of Things (IoT) is a new concept that has been gaining momentum. With it, many companies and individuals can connect their devices with web-enabled apps. The IoT allows these devices to collect and share information, hold data, and also transmit it through the internet. Now we will break down the applications of IoT in the manufacturing industry. It will cover the uses that can be carried out by different industries like manufacturing, retail, transportation, etc. Also, it will provide an overview of how IoT can help firms achieve some business goals such as efficiency gains or better customer satisfaction.

- Intelligent product enhancements: The last few years have seen the emergence of several smart products that are now present in various industries. Some notable examples include smart thermostats, smart CCTV cameras, and even smart watches that enable timely notification regarding any incoming calls or messages. These devices may sound unnecessary for most individuals, but for companies with a high turnover rate, these products are crucial as they can improve customer delivery time. For example, a shipping company uses smart devices to identify the general location of its shipments. This process can help in avoiding delivery delays, providing quicker insight into available space within transportation yards/warehouses, and so on.

- Dynamic Response to market demands: The experience delivered by any industry is greatly influenced by how quickly it can respond to changes within its market. The IoT allows companies to read and respond more dynamically to market demands. For example, a company that has deployed interconnected smart sensors throughout its supply chain can react quickly when it comes to releasing new products. It all comes down to being able to predict customer interest better and rolling out products that match the requirements of most consumers, whose needs are always evolving. For more help with IoT services, HashStudioz can guide you through.

- Automated responses: IoT enables firms to automate responses towards certain operations, such as environmental monitoring, quality control checks, and so on. The use of such software can save the company time and money. Customers can also have more control over the manufacturer by enabling them to monitor its processes and operations.

- Improved customer experience: The advent of IoT devices allows firms to offer customers better services that are customized to their needs. For example, drivers can receive immediate updates on whether the fuel tank is full or not. This way, drivers no longer need to make unwise decisions on driver safety. These same benefits extend to consumers as well, by making it possible for them to customize their experiences with a particular manufacturer by installing smart devices in their homes or offices.

- The safety of the product: It is not to overlook the fact that despite taking several measures to ensure the safety of the customer, the safety hazards and dangers still manage to find their way into the market. There could be several undetermined reasons that could cause serious incidents. With the help of IoT in the manufacturing industry especially, it will help in the best possible ways to deploy sensibility, control, and management techniques to track such incidents and raise alerts in case of any potential threat. If you have been looking for ways in which you have the surety of the products being safe, then IoT development solutions from HashStudioz are all you need.

- Waste reduction, optimized resources, and lower costs: The Internet of things (IoT) tends to replace aspects of manual labor in several niches and industries. The aspect of IoT eliminates the dependency on humans to perform background checks on the products. Most of the time, manual labor is time-consuming and also comes with a cost. With the help of IoT, the manufacturing industries can eliminate the factor of cost and can also save time because, with the help of IoT, they will be able to monitor the status of their organization remotely. IoT can help in ways to manage and optimize the usage of resources, for instance, humans and minerals. Furthermore, it offers feasible and effective methods for most of the most complicated issues and problems.

- Quality control: With the help of IoT, one can witness real-time monitoring of appliances and various products in the industry. The manufacturers can foresee the breakdown of certain machinery parts and offer the best and most appropriate solution right away instead of waiting for the machine to break down and collapse. The IoT benefits the system by monitoring the status of engines, machinery, and other mechanisms. With the help of IoT services, the manufacturing industry will be able to cut down on its dependency on manual laborers.

- Smart packing: The internet of things is used in smart packaging, it uses technology to package goods and performs additional functions beyond simple storage. Users can engage with the package and find answers to their questions about the bread, the product, or the delivery.

- Digital metering: The use of smart meters makes it possible to consume resources most effectively and efficiently while also minimizing resource waste. The manufacturing sector will be able to monitor its consumption of power, fuel, and water thanks to smart meters. Measuring aids in the best ways to gauge how these resources are being used, after which strategies to support the best and most appropriate resource consumption are put to use.

- Workshop supervision: Machine workshops are precisely the stores where the production of materials and tools takes place. Additionally, these workshop monitoring systems tend to use a lot of energy inefficiently because there is a complicated energy flow throughout the production of these tools, which results in high energy consumption. To improve the situation, IoT creates an efficient monitoring system to gather and track the energy use by these workshops. The management of the production process by IoT results in lower costs and energy usage.

- Workshop supervision: Machine workshops are precisely the stores where the production of materials and tools takes place. Additionally, these workshop monitoring systems tend to use a lot of energy inefficiently because there is a complicated energy flow throughout the production of these tools, which results in high energy consumption. To improve the situation, IoT creates an efficient monitoring system to gather and track the energy use by these workshops. The management of the production process by IoT results in lower costs and energy usage.

Wrapping up,

The industrial internet of things in manufacturing and businesses helps to maximize productivity, reduce and eliminate wastage, and cut down the factor of cost. By making use of IoT technologies and data from an IoT Application Development Company, i.e., HashStudioz, you will be able to get a better understanding of the supply chain process. In addition, demand forecasting will result in a better customer experience, therefore it is never too late to leverage the aspect of IoT into the business.

Being at the heart of industrial manufacturers, IoT solutions from an IoT development company such as HashStudioz Technologies have created a subset for IoT technology, i.e., the industrial internet of things.

Original Source: https://hashstudioz.com/blog/iot-in-manufacturing-applications-and-benefits-explained/

Comments